Electro Discharge Machining

Waveney Precision Limited are one of very few specialist precision engineering companies in Norfolk/Suffolk that has the capacity and expertise to provide both EDM wire and EDM Sinking capabilities.

What Is Electro Discharge Machining?

Electro Discharge Machining or EDM as it is also known as a method in which material is removed from a workpiece using thermal energy. Very similar to laser cutting, EDM does not need any mechanical force as part of its removal process.

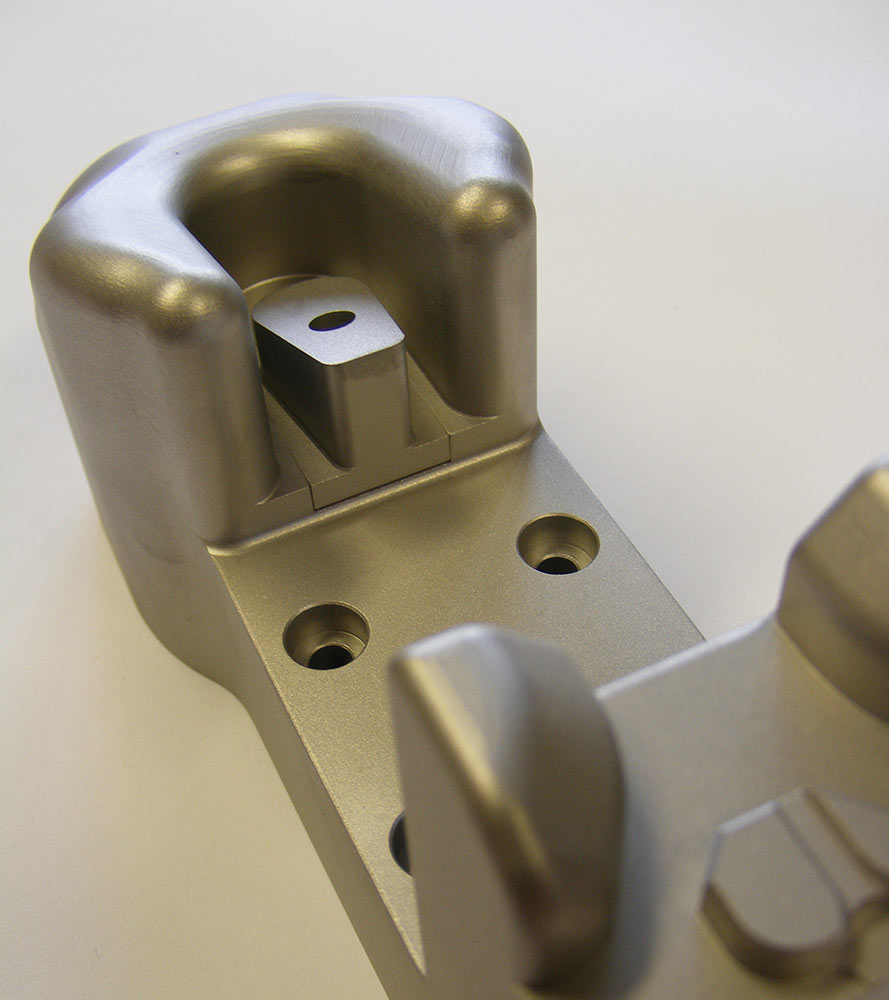

To be put more simply EDM is a manufacturing process that precisely removes material from a conductive material using an electrode. Controlled on a 5 axis, EDM technology enables the economic production of complex forms that cannot conventionally be produced in a single piece.

This non-contact process ensures no stress is placed on the component, enabling high tolerances to be achieved, avoiding distortion and leaving a surface that requires minimal additional finishing.

Get In Touch

What Other Services Do We Offer?

The advantages of EDM Wire and Die Sink are clear to see, with many of the Waveney Precision Limited clients taking advantage of this method. A few of the advantages include the following:-

Complex, contoured shapes can be produced in one piece rather than several, in the exact configuration that is required. This can eliminate or reduce fixture and tooling costs.

Waterjet Cutting

Due to lower machining forces, this allows for tighter tolerances of up to 2 microns to be achieved. With little or no stress imparted on the work, online clamping is necessary.

Wire EDM cutting is a highly efficient method of accurately producing prototype parts, making the trial stamping of parts whose final shape it not yet determined unnecessary